LS engines, known for their efficiency and versatility, have become popular in automotive swaps․ Pairing them with manual transmissions like the T56 or TR6060 offers enhanced control and performance, making them a favorite among enthusiasts for custom builds and upgrades;

1․1 Overview of LS Engine Family

General Motors introduced the LS engine family, known for its efficiency and lightweight design․ These engines feature aluminum blocks, varying displacements, and advanced technologies․ LS engines are popular in high-performance and everyday vehicles, offering reliability and versatility․ Their broad range includes LS1, LS2, LS7, and more, making them ideal for swaps and custom builds․

1․2 Benefits of Pairing LS Engines with Manual Transmissions

Pairing LS engines with manual transmissions enhances precision and control, offering a more engaging driving experience․ The lightweight design of LS engines complements manual transmissions, improving fuel efficiency and responsiveness․ This combination is ideal for performance-driven builds, providing a seamless connection between driver input and vehicle performance, making it a favorite among automotive enthusiasts․

Popular LS Engine Variants for Manual Transmission Swaps

The LS1, LS2, and LS7 engines are popular choices for manual transmission swaps due to their compatibility with the T56 and TR6060 transmissions, offering powerful and smooth performance․

2․1 LS1 Engine Specifications and Compatibility

The LS1 engine, a 5․7L V8, is highly compatible with manual transmissions like the T56․ It produces 350-400 horsepower, making it a popular choice for swaps in vehicles requiring a balance of power and efficiency, often used in classic cars and performance builds due to its lightweight and strong performance capabilities․

2․2 LS2 Engine Overview and Swap Considerations

The LS2 engine, a 6․0L V8 producing 400-425 horsepower, offers significant power for manual transmission swaps․ Slightly heavier than the LS1, it requires careful consideration of vehicle weight distribution and chassis modifications․ Compatible with transmissions like the T56, it often needs adapter plates and flywheel adjustments for seamless integration․

2․3 LS7 Engine Performance and Manual Transmission Pairing

The LS7, a 7․0L V8 producing 505-510 horsepower, is a high-performance engine ideal for manual transmission swaps․ Paired with a T56 or TR6060, it delivers exceptional power delivery․ Key considerations include a high-stall torque converter for automatics or a compatible flywheel and clutch for manuals, along with a robust exhaust system to maximize performance․

Manual Transmission Options for LS Engine Swaps

The T56 and TR6060 are popular manual transmissions for LS swaps, offering compatibility and performance․ Other options like AX15 and 4L60E are also considered, ensuring robust and reliable setups․

3․1 T56 Transmission: Features and Compatibility

The T56 transmission, renowned for its durability, is a popular choice for LS engine swaps․ It offers smooth shifting and robust torque capacity, making it ideal for high-performance applications․ Compatibility with LS engines is excellent, though modifications like shifter placement and flywheel alignment may be necessary for seamless integration into classic or modern vehicles․

3․2 TR6060 Transmission: Advantages and Installation Tips

The TR6060 transmission, known for its strength and smooth shifting, is ideal for high-performance LS swaps․ It features a robust design and excellent gear ratios․ Installation requires an adapter plate for proper mounting and may need shifter modifications for optimal performance in both classic and modern vehicles․

3․3 Other Manual Transmission Options (AX15, 4L60E, etc․)

Beyond the T56 and TR6060, enthusiasts can explore the AX15 and 4L60E․ The AX15 offers durability with a compact design, suitable for lighter swaps․ The 4L60E, an automatic, becomes manual via conversion kits, providing versatility․ Both options require specific adapters and modifications for seamless integration with LS engines․

Key Considerations for LS Engine and Manual Transmission Swaps

Ensuring proper engine and transmission mounting, flywheel compatibility, and wiring configurations are critical․ Addressing ECU settings and mechanical adaptability ensures a smooth and reliable swap process․

4․1 Engine and Transmission Mounting Solutions

Proper engine and transmission mounting is essential for stability and performance․ Use durable engine mounts and transmission crossmembers to align components correctly․ Custom or aftermarket solutions may be needed for specific vehicle frames․ Ensuring proper alignment prevents vibration and misalignment issues, while frame reinforcements can enhance structural integrity for heavy-duty applications․

4․2 Flywheel and Clutch Compatibility

Ensuring compatibility between the flywheel and clutch is critical for smooth operation․ LS engines typically require a flywheel designed for manual transmissions, paired with a high-quality clutch kit․ Proper alignment and compatibility ensure optimal performance and prevent mechanical issues․ Always verify specifications to match the engine and transmission setup for reliability․

4․3 Wiring and ECU Configuration

Proper wiring and ECU configuration are crucial for seamless LS engine and manual transmission integration․ Ensure the engine harness connects correctly to the chassis harness using accurate pin-outs․ Integrate transmission sensors to avoid errors․ Correct ECU setup is vital for manual transmission recognition, preventing issues like incorrect gear readings and ensuring smooth, efficient performance․

Step-by-Step Installation Guide

A step-by-step guide to installing an LS engine with a manual transmission involves preparing the vehicle, installing the engine, integrating the transmission, and performing final tests․

5․1 Preparing the Vehicle for the Swap

Preparing the vehicle involves removing the old engine and transmission, inspecting the chassis, and modifying suspension or crossmembers as needed․ Ensure cooling and fuel systems are compatible with the LS engine․ Wiring and ECU adjustments are critical, along with verifying shifter and pedal compatibility for a smooth integration․

5․2 Installing the LS Engine

Installing the LS engine requires careful alignment and mounting․ Secure the engine using compatible mounts and ensure proper clearance․ Connect the engine harness to the chassis harness, verifying pinouts for compatibility․ Install hydraulic systems, ensuring components from 2001 or newer are used․ Check cooling and fuel systems for compatibility and functionality before proceeding․

5․3 Integrating the Manual Transmission

Install the manual transmission by aligning it with the LS engine, ensuring proper drivetrain alignment․ Use compatible mounts and secure the transmission․ Connect the shifter, verifying its placement matches the vehicle’s layout․ Ensure the flywheel and clutch are compatible, and all bolts are tightened properly for secure integration and smooth operation․

5․4 Final Testing and Tuning

After installation, perform a thorough inspection for leaks and proper connections․ Test the transmission and clutch operation, ensuring smooth shifting․ Tune the ECU for optimal performance and verify wiring functionality․ Address any minor issues promptly to ensure reliable operation and maximize the benefits of the LS engine and manual transmission combination․

Common Challenges and Solutions

Common challenges include wiring issues, mechanical compatibility, and transmission adaptation․ Solutions involve proper ECU configuration, specialized adapters, and professional tuning to ensure seamless LS engine and manual transmission integration․

6․1 Overcoming Electrical and Wiring Issues

Electrical challenges often arise from incompatible harnesses and ECUs․ Ensure correct pin-outs for LS engine and chassis connections․ Use a wiring harness adapter or standalone ECU for manual transmissions․ Consult forums or professionals for troubleshooting, as incorrect configurations can lead to sensor malfunctions or engine errors․

6․2 Addressing Mechanical Compatibility Problems

Mechanical issues often stem from misaligned components․ Ensure engine mounts and transmission crossmembers are compatible․ Use adapters or custom mounts if necessary․ Verify flywheel and clutch alignment with the LS engine․ Bellhousing spacers may be required for proper fitment․ Always check drivetrain components for compatibility to avoid vibration or operational issues․

6․3 Troubleshooting Common Swap-Related Issues

Common issues include misfires, wiring harness incompatibility, and ECU configuration problems․ Check engine codes for specific faults․ Ensure proper fuel pressure and spark delivery․ Verify transmission installation alignment to avoid drivetrain vibrations․ Addressing these issues early prevents costly repairs and ensures smooth operation of the LS engine and manual transmission setup․

Maintenance and Upgrades for LS Engine and Manual Transmission

Regular oil changes and filter replacements ensure LS engine longevity․ Upgrading with performance cams or intakes boosts power․ Manual transmissions benefit from gearset upgrades and shift kit installations for enhanced durability and performance․

7․1 Routine Maintenance Tips

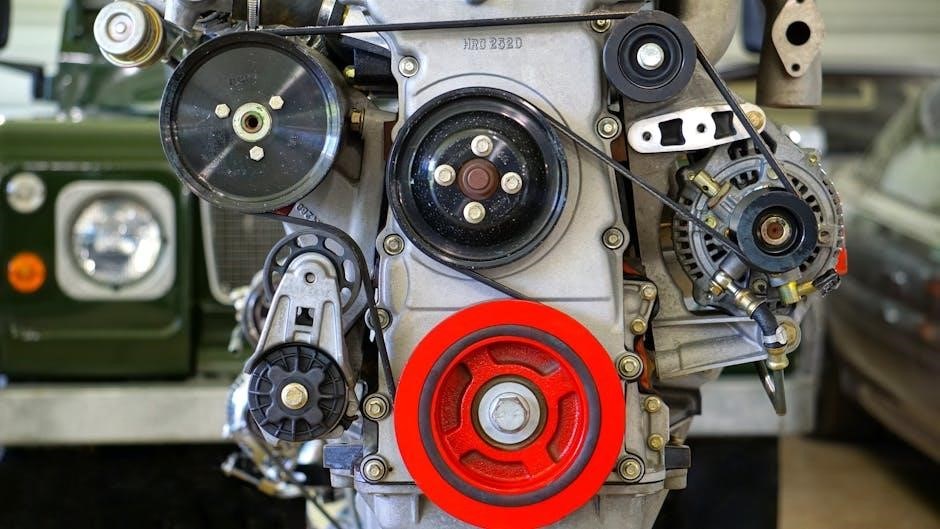

Regular oil changes and filter replacements are essential for LS engine health․ Inspect belts, hoses, and fluid levels regularly․ Check transmission fluid and ensure proper gear lubrication․ Replace spark plugs as recommended and update engine software for optimal performance․ These routine practices ensure smooth operation and prevent costly repairs․

7․2 Performance Upgrades for the LS Engine

Upgrade your LS engine’s performance with a high-lift camshaft and ported cylinder heads for increased airflow․ Install a high-flow intake system and aftermarket exhaust to maximize power․ Consider adding a supercharger for significant horsepower gains․ Pairing these upgrades with a manual transmission like the TR6060 enhances drivetrain efficiency and overall performance․

7․3 Transmission Upgrades for Enhanced Performance

Enhance your manual transmission’s performance with a lightweight flywheel and high-performance clutch for smoother shifting․ Upgrade to a billet input shaft and carbon synchros for durability․ Install a short-throw shifter for precise control and quicker gear changes․ These upgrades complement the LS engine’s power, optimizing overall driving dynamics and responsiveness․

Real-World Applications and Case Studies

LS engines with manual transmissions are widely used in classic car restorations, modern vehicle swaps, and performance builds․ Enthusiasts share success stories, highlighting durability and adaptability in various applications;

8․1 Successful LS Swap Projects in Classic Cars

Classic cars like the 1971 Corvette and vintage trucks have benefited from LS swaps with manual transmissions․ These projects highlight increased power, reliability, and a seamless driving experience․ Enthusiasts share their successes, showcasing how LS engines paired with T56 transmissions transform iconic vehicles while maintaining their timeless appeal and handling․

8․2 Manual Transmission Swaps in Modern Vehicles

Modern vehicles, including trucks and SUVs, are increasingly adopting LS engine swaps with manual transmissions․ These upgrades enhance performance and drivability, offering a blend of classic control and modern power․ Owners report improved fuel efficiency and a more engaging driving experience, making such swaps a viable option for contemporary automotive enthusiasts․

8․3 Lessons Learned from Experienced Enthusiasts

Experienced enthusiasts emphasize proper planning and compatibility checks when performing LS engine and manual transmission swaps․ Key considerations include flywheel alignment, adapter plate selection, and wiring harness modifications․ They also stress the importance of professional guidance for complex installations and troubleshooting common issues like misfires or transmission misalignments․

Cost and Budgeting for the Swap

Budgeting for an LS engine and manual transmission swap requires careful planning․ Costs include engine, transmission, adapter plates, and labor․ Researching parts and labor expenses is crucial for a successful project․

9․1 Estimating Parts and Labor Costs

Estimating costs for an LS engine and manual transmission swap involves detailing parts and labor expenses․ Engine prices vary widely depending on the variant, while transmission costs are influenced by type and condition․ Labor costs can range from $2,000 to $5,000, depending on the installer’s expertise and location․

9․2 Budget-Friendly Solutions and Alternatives

Consider reusing existing components like engine mounts or pedals to reduce costs․ Opting for a 5․3L engine instead of a 6․0L or LS7 can save money․ Used transmissions, such as the T56 or 4L60E, are often more affordable․ Additionally, sourcing parts from salvage yards or opting for a simpler swap kit can help lower expenses․

9․3 Long-Term Cost Considerations

Long-term costs include routine maintenance, potential transmission servicing, and upgrades․ LS engines are reliable, reducing long-term expenses․ Manual transmissions, like the T56, are durable but may require clutch replacements․ Fuel efficiency improvements can offset initial costs, while the engine’s longevity ensures a strong return on investment over time․

Tools and Resources for the Swap

Essential tools include engine harness pin-outs, transmission adapters, and specific wrench sets․ Online forums and communities provide valuable guides, while companies like Summit Racing offer tailored solutions and support․

10․1 Essential Tools for the Job

Key tools include a crankshaft socket, flywheel puller, and transmission jack․ Specialized wrenches for LS engines and a wiring harness diagram are crucial․ Additionally, a set of metric and SAE sockets, along with adapters for manual transmissions, ensures a smooth installation process․

10․2 Recommended Online Resources and Forums

Popular forums like LS1Tech and CorvetteForum offer extensive guides․ Websites such as Summit Racing and Jegs High Performance provide parts․ YouTube channels like LS Swap DIY and EricTheCarGuy share detailed tutorials․ Reddit communities, such as r/LSswap, are great for peer advice and troubleshooting tips․

10․3 Professional Services and Aftermarket Support

Companies like Summit Racing and Jegs High Performance offer aftermarket parts․ Specialized shops like Orange County Choppers and Tick Performance provide custom builds․ Advance Adapters specializes in LS swap kits․ Professional services include installation, tuning, and custom fabrication, ensuring a seamless integration of LS engines with manual transmissions for optimal performance․

DIY vs․ Professional Installation

DIY installations offer cost savings and personal satisfaction but require technical expertise and time․ Professional installations ensure reliability and expertise, though at a higher cost, making them ideal for complex swaps․

11․1 Pros and Cons of DIY Swaps

DIY LS swaps offer cost savings, personal satisfaction, and customization․ However, they require mechanical expertise, specialized tools, and significant time․ Potential risks include compatibility issues, electrical challenges, and improper installations, which can lead to costly repairs or performance setbacks, making thorough preparation and research essential for success․

11․2 When to Hire a Professional

Hiring a professional is advisable for complex tasks like wiring, ECU configuration, or custom mounts․ Experts ensure compatibility, proper installation, and optimal performance, minimizing risks of costly errors․ This is particularly beneficial for those with limited experience or time, ensuring a reliable and efficient swap process from start to finish․

11․3 Tips for Collaborative Projects

Collaborative projects thrive on clear communication and defined roles․ Leverage collective expertise by assigning tasks based on strengths․ Regular updates and transparent feedback ensure alignment․ Utilize online forums and resources for guidance․ Consider professional input for critical steps, fostering a team environment that enhances creativity and problem-solving, leading to a successful swap outcome․

LS engine and manual transmission swaps remain a popular modification, with advancements in technology and aftermarket support driving innovation․ Future trends include improved efficiency and more seamless integration solutions․

12․1 Summary of Key Takeaways

LS engine swaps with manual transmissions offer enhanced performance and control, popular among enthusiasts․ Common options include T56 and TR6060 transmissions․ Key considerations involve wiring, mounting, and compatibility․ Overcoming electrical and mechanical challenges is crucial; Strong aftermarket support and community resources aid success, ensuring continued popularity and innovation in future automotive projects․

12․2 Emerging Trends in LS Engine and Manual Transmission Swaps

Emerging trends include increased interest in hybrid LS swaps with electric systems, lightweight transmission options, and improved fuel efficiency․ Enthusiasts are also exploring modern engine management systems paired with manual transmissions for enhanced performance․ Online forums and communities continue to drive innovation, fostering creative solutions and pushing the boundaries of LS engine applications․